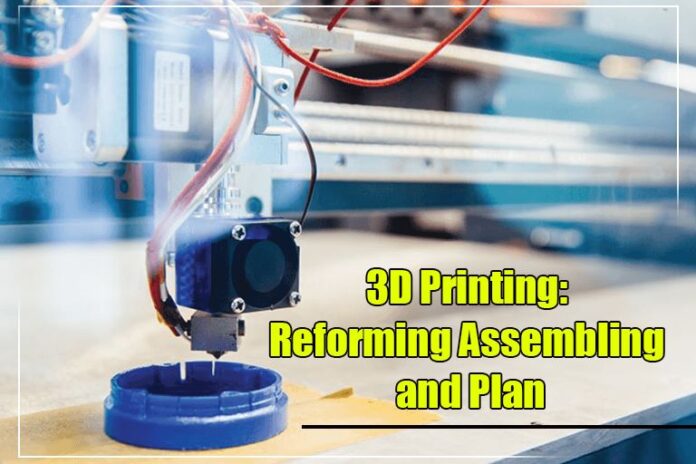

The coming of 3D printing, otherwise called added substance producing, has ignited extraordinary unrest in the fields of assembling and planning. This noteworthy innovation has upset how we make, model, and assemble items. By empowering the creation of perplexing three-layered objects with unparalleled accuracy, speed, and customization, 3D printing has arisen as a distinct advantage across ventures. This article investigates how 3D printing has changed assembling and configuration, carrying development and proficiency to an unheard-of level.

- Unleashing Inventiveness and Plan Opportunity

One of the main benefits of 3D printing is the unmatched planning opportunity it offers. Customary assembling techniques frequently force limits on item intricacy and plan multifaceted nature. With 3D printing, be that as it may, these requirements are broken, permitting architects and designers to release their inventiveness without limits. Complex calculations, natural shapes, and mind-boggling interior designs can be easily converted into actual items utilizing 3D printing advances.

- Prototyping and Quick Emphasis

3D printing has decisively sped up the prototyping system, permitting fashioners and designers to repeat rapidly and productively. Conventional prototyping techniques frequently include tedious and exorbitant cycles, for example, CNC machining or infusion shaping, which require devoted tooling and broad arrangement time. Interestingly, 3D printing empowers quick prototyping by creating actual models straightforwardly from computerized plans. This capacity to print useful models surprisingly fast or days has fundamentally abbreviated item improvement cycles and enabled architects to repeat and refine their plans more quickly than at any other time.

- Customization and Personalization

One more extraordinary part of 3D printing lies in its capacity to empower mass customization and personalization of items. In customary assembling, customization frequently comes for an extreme price because of the requirement for particular tooling or sequential construction system reconfiguration. Notwithstanding, 3D printing takes into consideration the on-request assembling of customized items without causing extra costs. Whether it’s making specially fit prosthetics, remarkable gem pieces, or customized shopper products, 3D printing has made mass customization a possible and reasonable reality.

- Reduced Waste and Practical Assembling

3D printing presents a harmless to the ecosystem option in contrast to customary assembling strategies. The added substance nature of 3D printing wipes out the requirement for subtractive cycles, for example, cutting or processing, which produce huge waste. By building objects layer by layer, 3D printing decreases material waste and energy utilization. Moreover, 3D printing empowers the utilization of reused materials and biodegradable fibers, further advancing maintainable assembling rehearses. This innovation can reform supply chains by decreasing transportation and capacity costs through confined creation.

- Complex Item Advancement and Modern Applications

Past fast prototyping and customization, 3D printing has opened up new outskirts in complex item improvement. Ventures like aviation, auto, medical services, and design are utilizing 3D printing to create multifaceted parts, lightweight designs, and, surprisingly, whole structures. The capacity to print leaves behind complex inside calculations and advanced plans has prompted superior execution, diminished weight, and upgraded usefulness in different applications. Besides, 3D printing has worked with the development of patient-explicit clinical inserts, prosthetics, and physical models, empowering customized medical care arrangements.

- Challenges and Future Potential

While 3D printing has taken wonderful steps, there are still difficulties to survive. Increasing creation speed, working on material choice, and upgrading printer dependability are regions that require progressing innovative work. Nonetheless, as headways proceed, 3D printing holds gigantic potential for reforming different ventures further. From space investigation to maintainable assembling, the opportunities for this innovation are huge.

- 3D Imprinting in Schooling

The openness and reasonableness of 3D printers have made them priceless devices in instructive settings. Schools and colleges are integrating 3D printing into their educational plans, permitting understudies to investigate configuration thinking, designing standards, and critical thinking abilities. Understudies can rejuvenate their ideas, changing theoretical thoughts into substantial items. This involved experience cultivates imagination, decisive reasoning, and development, planning understudies for future vocations in fields where 3D printing assumes a critical part.

- Disrupting Inventory Chains and Assembling Standards

Customary assembling frequently includes perplexing and extensive stockpile chains, with items being fabricated in one area, gathered in another and appropriated worldwide. 3D printing can upset these stock chains by empowering restricted creation. With the capacity to print items on location or close to the mark of purpose, transportation expenses and lead times can be altogether diminished. This decentralized assembling model has suggestions for different enterprises, including spare parts creation, quick reaction to advertising requests, and diminished stock prerequisites.

- Bioprinting and Clinical Leap forwards

One of the most uplifting and huge purposes of 3D printing is in the field of bioprinting. By using specific printers and bio-inks made from living cells, analysts and experts are examining the possible results of printing human organs, tissues, and, shockingly, complex regular plans. Bioprinting holds tremendous potential for organ transplantation, regenerative medicine, and prescription testing; offering anticipates that tending should the organ need crisis and further creating clinical benefits results.

- Industrial 3D Printing and Direct Assembling

Modern grade 3D printers have extended the abilities of added substance producing past prototyping and customization. With progressions in innovation, materials, and printing processes, 3D printing is progressively used for the direct assembling of end-use items. From car parts to buyer merchandise and modern apparatus, 3D printing is being incorporated into creation lines, empowering on-request fabricating, decreasing tooling costs, and the development of complicated calculations that are challenging to accomplish through conventional techniques. This shift towards direct assembling can smooth out creation, upgrade item quality, and change supply chains.

Conclusion:

3D printing has upset assembling and configuration, affecting different areas and pushing the limits of development. From space investigation and customized medical services to innovative enterprises and economical practices, the utilization of 3D printing is tremendous and extensive. As the innovation develops and turns out to be more open, its true capacity for interruption and positive change keeps on developing. Embracing the open doors presented by 3D printing while at the same time addressing the related difficulties will be critical to saddling the maximum capacity of this game-evolving innovation. The upset has just barely started, and the fate of assembling and configuration holds invigorating potential outcomes through 3D printing.

Read more.. 10 Inventive Home-Based Startups Altering Our Residing Spaces

Read more.. The Client-Driven Approach: Conveying Uncommon Help and Building Unwaveringness